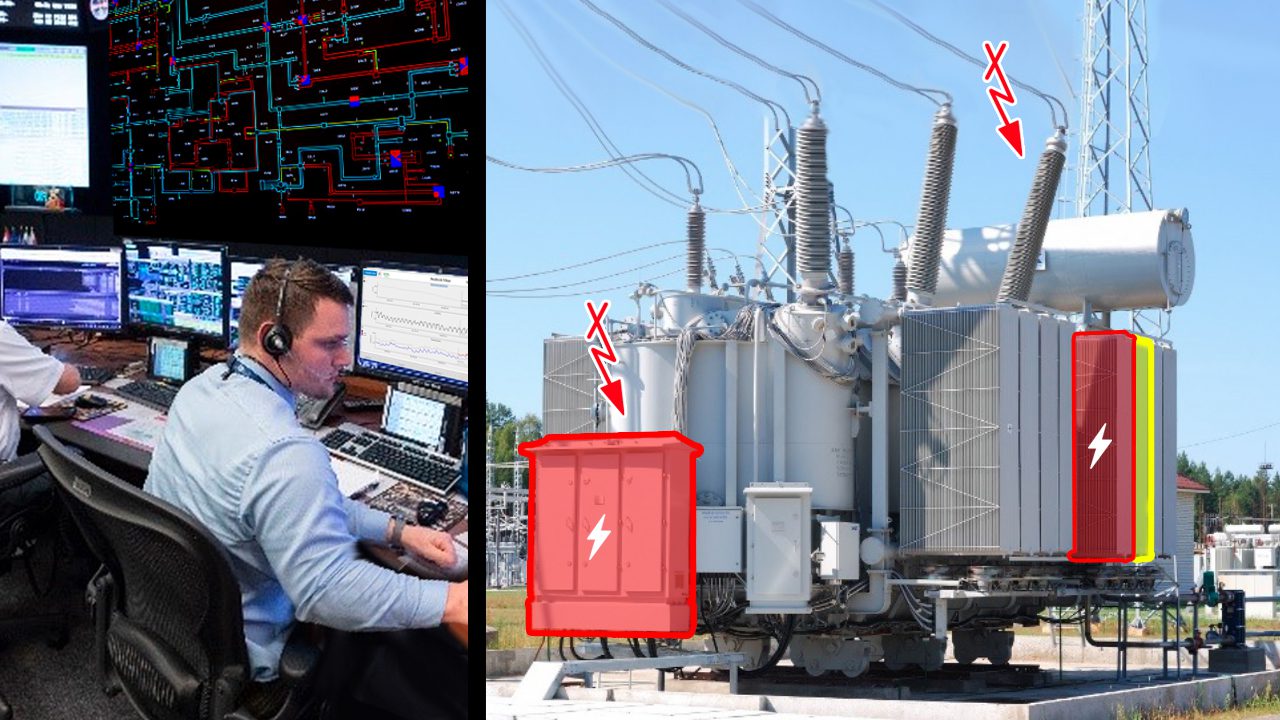

Charles River Analytics received a $1.1 million sequential Phase II Small Business Innovation Research (SBIR) contract to deliver condition-based maintenance of electrical transformers to keep critical power systems running. Probabilistic Operations Warranted for Energy Reliability Evaluation and Diagnostics (POWERED) integrates large amounts of available transformer data to diagnose equipment health and predict the possibility of system failures. Such proactive maintenance can prevent catastrophic shutdowns and save millions of dollars lost to expensive downtime and damaged equipment.

“POWERED capitalizes on our robust expertise in predictive maintenance. Electrical transformers are exceptionally good candidates for such condition-based maintenance because there’s a lot at stake if one breaks down,” says Dr. Sanja Cvijic, Senior Scientist at Charles River Analytics and Principal Investigator of POWERED. Replacing a transformer can be a very costly procedure in terms of both time and money. “It makes sense to invest a little bit in AI predictive health maintenance tools that can warn when degradation is happening so crews can prepare ahead of time and reduce overall downtime and blackouts,” Dr. Cvijic says.

The thousands of daily datapoints that the digital instrumentation on today’s transformers generate make ample fodder for artificial intelligence–based predictive analytics. “Dissolved gas analysis, a technique used to diagnose transformer health, used to be done every six to twelve months. Today’s tools can conduct oil sampling every hour,” Cvijic says.

POWERED analyzes a variety of data: ambient temperature, electrical loading, temperature of the oil used as cooling encasing agent, composition of dissolved gases in oil, and more.

Physics-based or data-driven models alone prove ineffective in capturing the diversity of variables to be analyzed. POWERED’s hybrid AI approach extends both types of models as needed: physics models that capture physical phenomena and data-driven simulations when physics models are not available. “The idea is that instead of developing a model from scratch, you reuse different models and chain them together to run end-to-end inference on the unified model,” Cvijic says.

Scruff™, the in-house probabilistic and modeling framework from Charles River Analytics, facilitates such integration of various models. Using this approach allows users to develop a tailored method instead of applying a one-size-fits-all tactic to every kind of sensor data. “The hybrid-component model allows you to infer each of the different aspects—temperatures, gas composition, etc.—differently, whereas if you lumped all that in a single model, you would sacrifice accuracy and explainability,” Cvijic says.

“Scruff is a good fit because it allows you to put together models quickly and then provides a library of inference algorithms that you can use to answer questions about that model,” Cvijic says.

POWERED’s results are easy to visualize and facilitate faster decision-making. In the interest of explainable AI, “we created a dashboard that is modular and provides full visibility into what the model believes at any time,” Cvijic says. Users are able to mix and match variables to study their correlations at any point in time.

While POWERED was originally created as a tool for the military, distribution and power companies represent a significant group of potential beneficiaries.

After iterative user-tested improvements, POWERED has the potential to expand beyond servicing transformers. “There’s lots of potential to create a power suite of tools that can be geared toward different types of equipment,” Cvijic says.

Contact us to learn more about POWERED and our capabilities in probabilistic programming and energy efficiency.

This material is based upon work supported by the Small Business Innovative Research (SBIR) Program and the Engineering Research and Development Center (ERDC) – Construction Engineering Research Laboratory (CERL) under Contract W9132T-20-C-0009. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the SBIR Program and ERDC-CERL.