Predictive Maintenance and Logistics

From predicting faults in equipment early to planning logistics in contested environments, our advanced AI capabilities help optimize sustainment for mission performance

Why it matters

Traditional maintenance relies on fixed schedules or post-failure reactions, leading to high operational costs, unnecessary maintenance, and avoidable downtime. Our predictive maintenance and logistics capabilities integrate hybrid AI, advanced modeling and simulation, and ecological human-machine interfaces to enable warfighters to anticipate failures and inform the right sustainment action at the right time and place. By linking prognostic health monitoring (PHM) reasoning directly to resource planning, we help ensure that crews, fleets, and supply chains remain ready and resilient, even in contested and resource-constrained environments.

Advanced Predictive Maintenance

and Logistics Capabilities

Our AI-enabled sustainment software services support real-time needs from the tactical edge by connecting distributed and embedded monitoring systems with operational and sustainment decision-making, as well as theater-level planning. These capabilities reduce manual workload, mitigate readiness risks such as extended downtime and production delays, and give commanders expanded optionality for sustaining fleet health and improving mission reliability at sea and on land.

Reliability Engineering Tools

Digital engineering tools and services that connect reliability forecasting to mission effectiveness.

Predictive Logistics Software

Advanced modeling, analytics, and agent-based simulation for supply chain and distribution forecasting even in contested environments.

CBM Prediction and

Inference Engine

Intelligent, on-platform engine that provides advance notification of impending component failures.

Intelligent CBM Workbench

A reconfigurable visual dashboard to monitor, analyze, and address system health and status.

AI Maintenance Aids

Software that processes text and translates technical documentation into on-demand adaptive training content and automates the process of filling out maintenance forms.

Predictive logistics modeling

for maritime and land operations

Our advanced AI software capabilities address critical challenges across reliability, CBM, logistics, and operational readiness.

Catch and address sustainment issues during system design

Integrating reliability forecasting with mission-level analytics helps design engineers not only understand how system performance impacts mission success and availability but also perform probabilistic trade-offs directly inside familiar MBSE environments.

Prevent failures that impact missions

Reliability forecasting and onboard AI-driven prognostics provide advance notification of impending failures, enabling crews to prioritize repairs, prevent equipment loss, and sustain mission readiness.

Understand system health and operational impacts

Visualize system health, trends, and anomalies for faster, higher-confidence decisions. Human-AI teaming interfaces simplify complex maintenance and logistics data, minimizing operator cognitive load and errors.

Accelerate repairs with better understanding and fewer manual steps

Convert technical documentation into interactive, job-specific training content and assist the completion of required forms and documentation.

Connect logistic scenarios and forecasts to mission outcomes

Probabilistic reliability forecasting and “what-if” trade studies increase fidelity for sparse logistics data, lowering the cost of reliability studies and enabling higher-confidence logistical decision-making and planning.

Rapidly generate valid logistics plans

Agents trained with deep reinforcement learning (DRL) generate campaign-scale, threat-aware plans and sustainment COAs in hours (not weeks).

Mitigate data silos and ensure data security

Connect global supply chains to asset- and site-level demand signals, ensuring seamless integration and optimized distribution networks. Embedded applications and RMF-compliant software ensure secure operations in disconnected environments.

Expert Voices and Media

Advanced predictive maintenance and logistics technologies will enable the Navy to transition from reactive to proactive maintenance strategies.

A conversation on predictive maintenance, cybersecurity, and decision support in high-stakes defense environments, exploring how explainability, adaptability, and human-centered design underpin the creation of trustworthy AI.

A conversation on advancing human-AI teaming, highlighting tools that support real-world decision-making and the importance of designing technology that puts people first in defense and civilian applications.

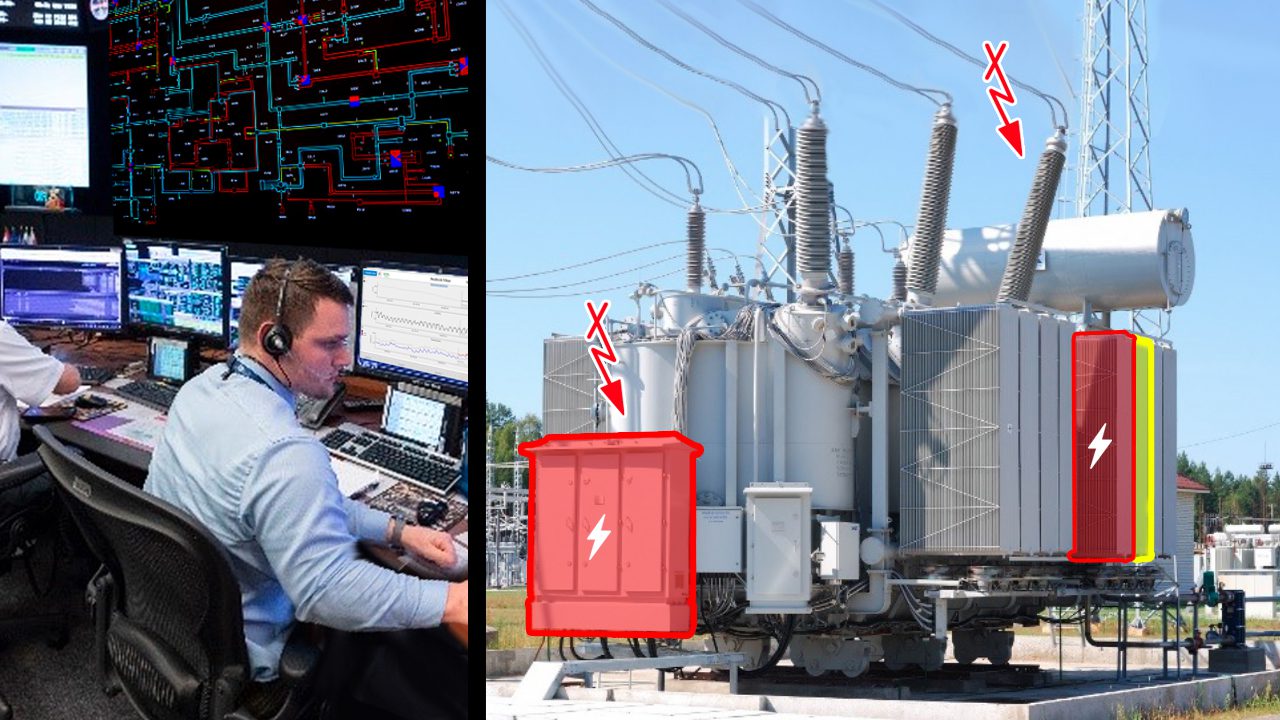

A prognostic and diagnostic application that helps operators maintain reliable power supplies and anticipate future risks.

Why choose

Charles River Analytics

Our multidisciplinary team at Charles River Analytics has led AI research for decades, advancing system modeling and hybrid AI reasoning with a foundation in cognitive systems engineering. Our advanced capabilities are transparent and explainable, helping users understand how the system reaches its conclusions. We make complex analytics accessible to non-engineers by emphasizing trust, clarity, and intuitive interfaces.

Publications / Advancing Research

Our publications demonstrate how advanced R&D in reliability engineering, predictive analytics, and logistics modeling strengthens mission readiness. From tools that forecast system health to platforms that optimize supply chains, this research highlights Charles River’s commitment to resilient, cost-effective solutions for defense and commercial operations.

In this paper, we present novel research that alleviates this problem by enabling non-AI/ML experts to create and maintain AI/ML applications with minimal guidance from a data scientist.

Read More

In this paper, we present novel research that leverages the power of probabilistic programming and hybrid AI that combines domain knowledge with data to create an effective analytic capability that monitors (in real time) the health and status of a robotic combat vehicle.

Read More

In this paper, we present insights into the importance of predictive maintenance and provide examples of implementation of predictive maintenance in uncrewed platforms such as robotic combat vehicles (RCVs). Moreover, we will discuss how AI techniques rooted in probabilistic models serve as a foundation for predicting health and status of uncrewed platforms.

Read More

In this paper we present Probabilistic Operations Warranted for Energy Reliability Evaluation and Diagnostics (POWERED), a hybrid AI and machine learning tool for diagnosing transformer health and predicting both performance and remaining useful life (RUL) to improve reliability and inform maintenance.

Read More